Jeep Shakes When Accelerating: 11 Major Causes And Their Fixes

It can be worrisome if your Jeep starts shaking when you accelerate. Don’t panic! I’ve got your back. Shaking during acceleration is a common issue for Jeep owners, and it can happen for various reasons.

Shaking in your Jeep may result from imbalanced tires, loose wheels, worn spark plugs, suspension problems, damaged motor mounts, a damaged CV joint, a bent or damaged driveshaft, or a bad U-joint.

Whether it’s vibrating or shuddering when you’re accelerating, there are potential warning signs of more significant problems.

In this troubleshooting guide, I’ll walk you through a step-by-step process to figure out why your Jeep shakes when accelerating and explore ways to fix it.

Table of Contents

What Does It Mean for Jeep to Shake When Accelerating?

If your Jeep shakes when you step on the gas, it can be confusing, right? Let’s break it down.

If you notice a noticeable shake while accelerating, you’re not alone. Many Jeep owners have experienced this issue.

The shake usually kicks in during acceleration, especially under heavy acceleration, and you may feel it more around 2500-3000 rpms.

Now, the shake can vary. For some, it happens for a short duration (5-10 seconds) when starting from a stop, almost like a vibration in the front of the Jeep.

Others feel it between 55-70 mph, turning into a full-blown car shake, causing issues like popping out of gear in manual transmissions. There’s even a case where the vibration hits hard between 40-60 mph.

The issue persists even after replacing the front CV axles and batteries and reprogramming the PCM under warranty.

You feel the wobble in the pedal and steering wheel, but it goes away when you ease off the gas.

So, why is your Jeep shaking when accelerating? It can be related to the drivetrain, engine, or other factors.

It’s a common issue, but don’t ignore it. Resolve the problem now to avoid bigger troubles down the road.

Is It Normal for a Jeep to Shake While Driving?

No, it’s not normal for a Jeep or any vehicle to shake while driving. If you’re experiencing shaking while driving, especially during acceleration, it’s usually a sign of an underlying issue that needs attention.

The causes can vary, ranging from problems in the drivetrain, suspension, or engine components.

Ignoring the shaking can lead to more significant problems and potential safety issues, so investigate and address the issue promptly.

If you’re unsure about the cause of the shaking, carefully go through the article below, and you’ll have an idea.

Why Is Your Jeep Shaking When You Accelerate?

If you experience shaking while driving, especially during acceleration, consider isolating the issue by temporarily removing the rear driveshaft and try testing your Jeep in 4WD high.

If the vibrations cease, it indicates a potential problem with the rear driveshaft. Similarly, you can test the front driveshaft by removing the rear driveshaft.

Okay, now let’s understand the 11 possible causes behind this Jeep shaking issue and their potential solutions:

1. Imbalanced Tires

If you’ve put larger tires on your Jeep, ensure they are perfectly balanced. Imperfect balancing can lead to vibrations, especially at higher speeds.

This is vital to prevent issues like shaking or vibration, which can occur if your tires aren’t balanced correctly.

When you put a tire on a wheel, it may not have the exact same weight all around. This slight weight imbalance can become a small vibration as the tire rotates.

This vibration becomes more noticeable at higher speeds, and your steering wheel may shake.

Pay attention to where the shake comes from to determine which wheels are at fault. Your front wheels may need balancing if your steering wheel shakes. Your rear wheels need balancing if the vibration is sensed through your seat.

If you suspect imbalanced tires, take your Jeep back to the dealership to have them rebalanced.

To fix unbalanced tires, a tire installer will use a balancing machine. They’ll add small wheel weights to specific locations on the rim to achieve perfect balance.

Sometimes, adhesive wheel weights may fall off, leading to imbalance.

2. Loose Lug Nuts

If you’re experiencing a vibration in your Jeep, it may be more common than you think – loose lug nuts.

This seemingly simple problem can turn catastrophic if left unattended. A slight wobble in your wheel while driving can make it feel like your car is shaking.

Ignoring this issue may lead to lug nuts eventually loosening all the way, risking the possibility of your wheel falling off while driving – a situation you definitely want to avoid.

Always ensure you’re using the correct lug nut size to prevent complications.

If the vibration starts at a certain speed and becomes more noticeable at lower speeds, especially 10mph or less, it can be as simple as a loose wheel.

The gradual progression indicates a worsening problem. To confirm if lug nuts are the issue, use a wheel brace to check all your wheel lugs.

Ensure you’ve tightened them to the exact factory specifications. A low-speed wobble, unrelated to dynamic balance, may point to loose lug nuts.

Take a few moments to inspect your lug nuts with a torque wrench.

Consider rotating each tire to rule out an unbalanced or loose wheel if you have a spare wheel.

While it may take some time on a Saturday morning, this simple check won’t cost you a cent and can safely eliminate the possibilities of wheel balancing and loose lug nuts.

During this process, also check each tire for flat spots.

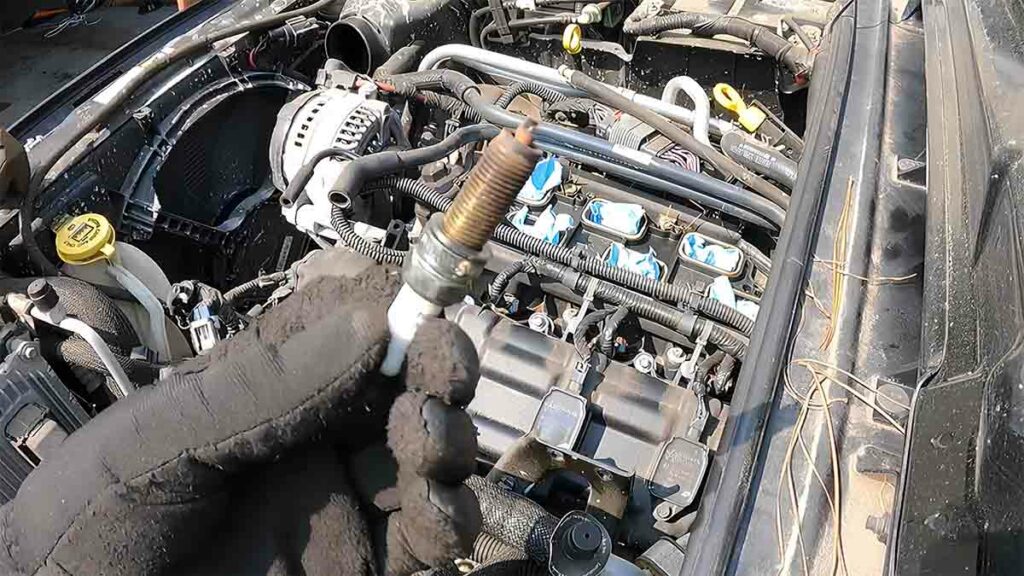

3. Dirty or Worn Spark Plugs

If your car is vibrating, worn or dirty spark plugs may be the issue. The engine may misfire as a result of dirty or damaged spark plugs, and this problem is frequently apparent when the engine is stopped.

However, it may also make your car feel like it’s vibrating while driving. If you haven’t replaced your spark plugs for a while, it may be time to do so.

When you remove one, a telltale sign of problematic spark plugs is a dark buildup on the tip.

If you observe this on one plug, there’s a good chance the rest of your spark plugs are in a similar condition.

Replacing dirty or worn spark plugs is simple and cost-effective and it can improve engine performance and smooth out any vibrations.

4. Bent or Damaged Driveshaft

If your Jeep operates with rear-wheel drive (RWD), power from the engine to the rear axle is delivered through the driveshaft.

Now, if this driveshaft is even slightly bent or damaged, perhaps due to an accident, it can lead to noticeable shaking when you accelerate at low speeds. As you pick up speed, the shaking only intensifies.

Whether you have a FWD, RWD, or 4WD, an unbalanced or damaged driveshaft can result in vibrations, even when you’re not actively accelerating.

In FWD setups, a malfunctioning driveshaft may go to each front wheel, while RWD systems may involve issues with the CV joint or the primary prop shaft that links the differential to the gearbox.

To diagnose a faulty driveshaft, you can drive your Jeep onto a ramp.

As the vehicle moves on the ramp, visually inspect the shafts to ensure they rotate smoothly around a fixed point.

If any damage is detected, prompt replacement is crucial to prevent further harm to the CV joints and other drivetrain components.

If you want to troubleshoot, try testing your Jeep in 4WD high. If the vibration disappears, it can indicate an issue with the rear driveshaft or universal joints.

There are several signs of a damaged driveshaft. The vibrations are most noticeable when you apply the gas. It is a strong indication that there is a drivetrain issue.

Unfortunately, you typically can’t repair a bent driveshaft, so replacing it is necessary to restore a smooth and safe driving experience.

5. Worn U-Joint

If you’re experiencing vibrations in your Jeep, one potential culprit may be a badly worn U-joint. Checking these components is a straightforward process that doesn’t require removing any parts.

Just take a quick crawl under your Jeep to inspect the U-joint jackets. Ensure they are correctly sealed with no indications of rust, water leaks, or grease leaks.

U-joints typically have a cross-shaped structure with caps on each end; some may even have a grease-able nipple.

A simple visual check will reveal their condition. Extending this inspection to the U-joints on the front wheels is also essential.

A bad U-joint can contribute to drivetrain vibrations, and it’s wise to inspect both the rear and front driveshafts for any slop in the U-joints.

If you notice that the U-joints feel wiggly or exhibit excessive play, replacing them as soon as possible is crucial.

The play in your drivetrain becomes significantly exaggerated when the driveshaft is spinning at high RPMs.

Vibrations near your transmission can indicate a problem with the U-joint closer to the transfer case.

If you observe a wobbling gear shifter that vibrates in sync with your speed, it’s a clear sign that the issue is related to a component nearby.

When it comes to replacing U-joints, opt for genuine parts, with the Spicer 5-760x being the recommended choice for Wranglers. It’s essential to address any wear or damage in these components promptly.

If you have a lift, consider installing a Slip Yoke Eliminator (SYE) kit and an aftermarket CV driveshaft.

This addresses U-joint angles and eliminates vibrations for a smoother driving experience.

6. Damaged CV Joint

Your Jeep’s CV joints, located at the end of each axle, are crucial in maintaining smooth wheel movement.

There are two joints: the outer and inner joints. Vibrations may occur during hard acceleration if the inner CV joint is damaged.

When under load, these slight vibrations can intensify into violent shaking as the damage worsens.

Damage to CV joints is caused by a rip in the joint boot. Water and dirt get inside the boot that protects the internal splines and pollute the grease.

The metal-on-metal contact will eventually fail if it is not properly lubricated. Replacing the CV joint or the entire CV axle is the only option.

To determine if your CV joint is worn, observe changes in noise or vibration, especially when turning corners.

If the vibration worsens, it can indicate a worn CV joint that requires replacement.

Additionally, visually inspect the rubber boot for any visible splits, which is a clear sign of potential CV joint damage.

7. Pinion Angle Issues

If your Jeep is shaking when you accelerate, the problem may be with the rear pinion angle.

Ensuring the proper pinion angle is crucial if you’ve lifted your Jeep by 2 inches or more. Adjusting the pinion angle is essential, especially if you’re experiencing vibrations.

If your control arms are stock, lowering the transfer case (T/C) skid plate by stacking washers around the mounting bolts can help.

8. T-Case Skid Plate Adjustment

If your control arms are stock and you have a lift, dropping the Transfer Case skid plate can be the solution. Stack heavy-duty galvanized washers (3/4” to 7/8” worth) between the frame and skidplate.

This helps reduce the excessive angle of the rear driveshaft, which can cause vibrations during acceleration.

9. Worn Yoke

A worn yoke in the drivetrain, especially the connection between the joint and yoke, can cause unwanted play and vibrations, particularly during acceleration.

To address this issue, replace the worn yoke to ensure a more stable and smoother driving experience.

10. Broken Engine/Motor or Transmission Cross-Member Mount

Your Jeep’s motor mounts are crucial in attaching the engine to the frame and reducing engine vibrations.

Made of a hard rubber material, they absorb these vibrations, ensuring a smoother ride. Excess vibrations become noticeable when a motor mount is damaged or broken, especially when idling or accelerating.

The shaking can become more pronounced under acceleration as the engine works harder.

The consequences of a damaged motor mount go beyond vibrations. If left unaddressed, other engine parts can misalign and break since the engine is no longer in its precise location. Replacing a bad motor mount is essential to stop these vibrations and prevent further damage.

It’s worth noting that a broken motor mount puts additional stress on the remaining mounts, increasing the likelihood of their failure.

If your Jeep shakes during acceleration, a broken or sheared transmission cross-member mount can be the culprit.

Despite seeming unrelated, a damaged mount can lead to vibrations. Once replaced and road-tested, you can confirm if this was causing the issue.

11. Control Arm and Suspension Issues

If you’re feeling shaking or vibrations when accelerating, it can be related to issues in the suspension system. Common problems include worn ball joints, responsible for the pivot between the suspension and wheels, and worn wheel bearings, crucial for smooth wheel rotation.

Damaged or worn-out shocks or struts can also contribute to shaking, especially at higher speeds.

Consider replacing the ball joints if your Jeep has clocked over 100,000 miles.

Signs of failing ball joints include clunking metal-on-metal noises from the front suspension, vibrations, and wandering or loose steering.

Inspect control arms and suspension components.

A worn-out control arm, particularly on the passenger side, can contribute to shaking. Replacing worn parts, including control arm bushings, can significantly reduce vibrations.

Keep an eye out for any signs of cracking or wear on the control arm bushing, as these indicate the need for prompt replacement.

Read More:

- Jeep Makes Clicking Noise When Opening The Door – Why? What To Do?

- Service Shifter Jeep Warning: How Do You Fix It?

Final Words

If your Jeep shakes when accelerating, there are several potential reasons for the shaking.

Identifying the specific cause of the vibrations in your Jeep and taking appropriate actions, such as balancing tires, checking lug nuts, maintaining spark plugs, inspecting the suspension system, addressing motor mount issues, replacing damaged CV joints, fixing a bent driveshaft, and ensuring healthy U-joints, will lead to a smoother and safer driving experience.

It’s crucial not to ignore the vibrations. Although it may seem like a minor annoyance, your car wasn’t designed to vibrate, and overlooking the issue can lead to more significant problems.

The good news is that addressing the problem early can save you from spending much on repairs later.